MRI machines and HVAC expertise.

When we talk heating and cooling, many people automatically think of air-conditioning to keep an office of home environment cool or refrigeration that keeps food cold. However, recently Chatfield OzCool worked on a project that is a great example of how HVAC expertise can be used in a medical setting.

In hospitals around the world, MRI (Magnetic Resonance Imaging) machines are a vital diagnostic tool offering insight and precision. This equipment is incredibly complex with many intricate moving parts that require pinpoint calibration.

One of the challenges with operating this equipment, is the incredible heat that is rapidly generated from the superconducting magnetic system of an MRI machine.

Enter, Chatfield OzCool.

Temperature management is vital in the stay safe and stable operation of an MRI.

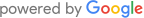

To manage this, all MRI machines have water that runs through them into the plant room. This keeps the machine cool during operation; and it is this water-cooling system, where Chatfield OzCool were able to utilise their refrigeration expertise.

How does temperature affect the operation of an MRI Machine:

- Superconducting magnetsin MRI scanners are kept at extremely low temperatures (around 4 Kelvin, or -269°C) using liquid helium.

- Thecryogenic system (cryostat) has heat exchangers and compressors that maintain these ultra-cold conditions.

- Thesehelium compressors generate significant heat during operation — and that’s where the water chiller comes in.

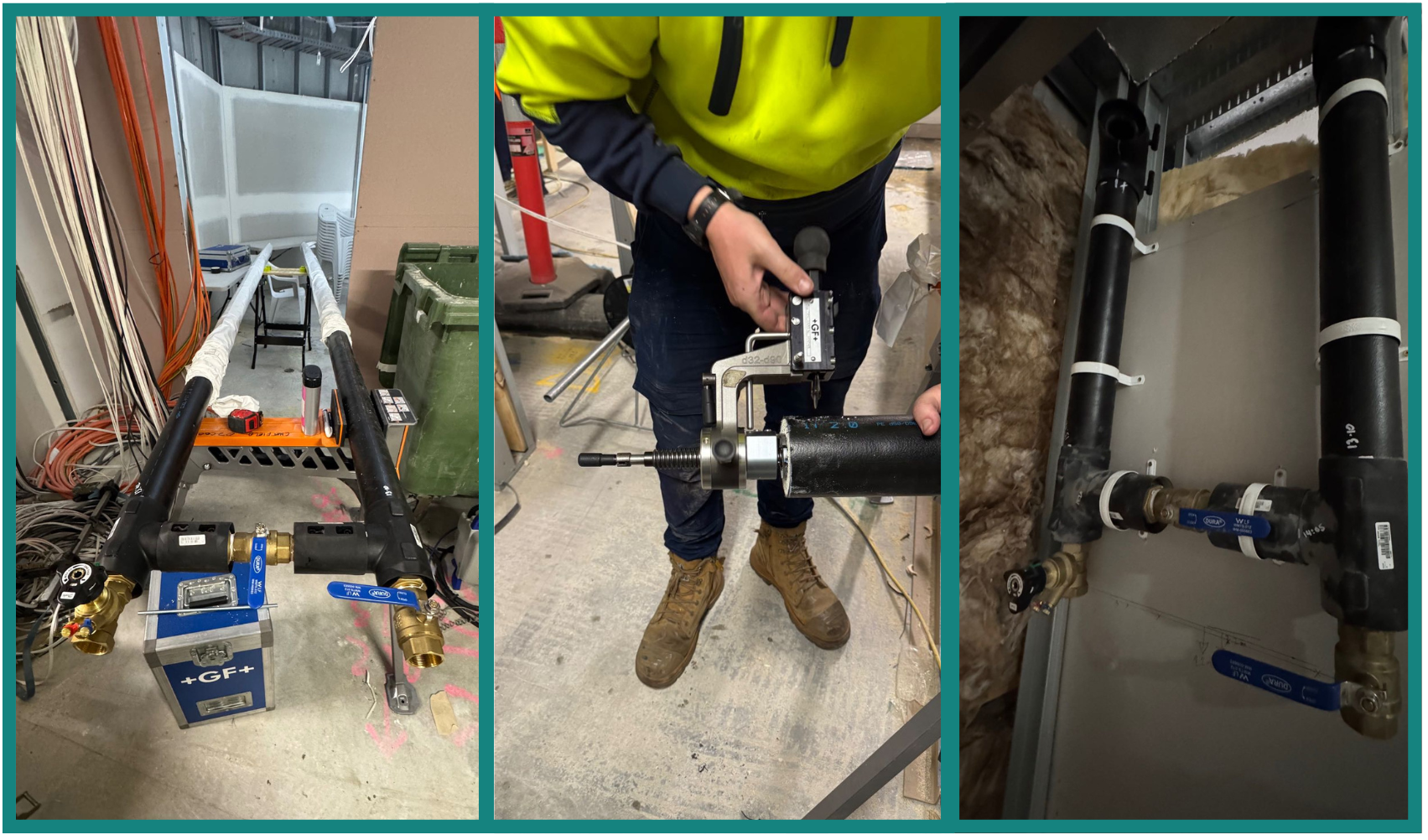

The chiller circulates cool water (or glycol–water mix) through the compressor’s heat exchangers to remove heat. (As demonstrated in the image below)

If the compressor overheats, the superconducting magnet could warm up, potentially causing a quench (loss of superconductivity).

How does water cooling support MRI machine functioning?

The gradient coils (which produce the time-varying magnetic fields for imaging) and RF amplifiers (which drive the radiofrequency pulses) also produce substantial heat during scans.

These components are often water-cooled to:

- Prevent overheating and thermal expansion (which would distort images)

- Maintain consistent performance and signal quality

- Prolong equipment lifespan.

What are the benefits of temperature stability and image quality?

MRI scanners need high thermal stability. Temperature fluctuations can:

- Affect magnetic field homogeneity

- Cause geometric image distortions or signal drift

A chiller provides steady cooling water at a constant temperature, helping maintain magnetic field stability and precise image calibration.

What is the typical chiller setup on an MRI Machine?

- Chiller unit:Located in a plant room or outside the MRI suite.

- Closed-loop cooling circuit:Carries chilled water (often 7–12°C) to and from the MRI equipment.

Flow and temperature sensors: Ensure proper

What happens in the chiller fails on an MRI machine?

If the water chiller malfunctions or shuts down:

- The helium compressor overheats → the cryostat may warm up → risk ofmagnet quench.

- The gradient system overheats → system shuts down or image artifacts appear.

- In short:MRI operation must stop immediately until cooling is restored.

With all the technology that goes into this type of machinery, isn’t it amazing that something as simple as ‘chilled water’ is the vital piece of the puzzle that keeps everything working smoothly.

We love the diversity of work we do at Chatfield OzCool, and this is another great example of HVAC skills being utilised in a unique environment.

If you would like to find out how we could help you, please give the team at Chatfield OzCool a call on 1300 361 186.

Click here to see what other services Chatfield OzCool can offer.